For most of us, we escape high school with a small group of close friends and a long string of acquaintances that litter our Facebook page. I’m not one to be too concerned with the lives of others, but one high school acquaintance recently caught my eye.

Nabeel Siddiqui started working at Modulus Tech.

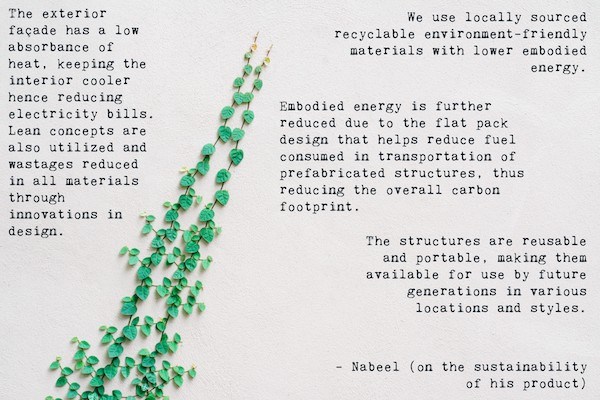

I found that the guitar-playing Nabeel that I knew, founded a start-up that produces low-cost flat-packed houses that can be set up in a mere 3 hours using minimal energy and sustainable materials. The products have a ‘DIY-Ikea’ approach whilst being kind to the earth.

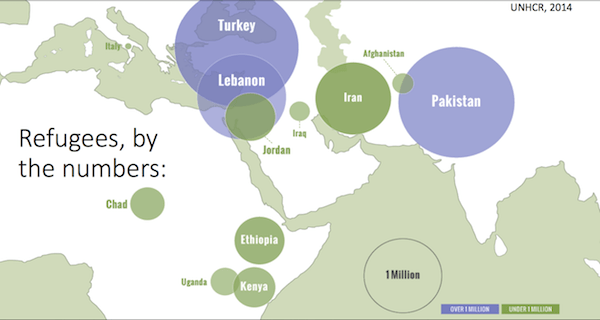

Nabeel himself is a civil engineer graduate from NED University, Karachi, who had the idea for Modulus Tech in the wake of the 2016 Syrian Refugee Crisis. Such migrations result in a large influx of people into a region over a short span of time. As lack of resources makes proper shelter near impossible, refugees often end up in tents and camps with poor living conditions leading to an outburst of social problems and epidemics.

He was further pushed to tackle this problem due to the state of his own country, Pakistan, which harbors a large proportion of displaced people and refugees.

The final cog in the ModulusTech mission came with Nabeel’s increasing interest in environmentalism. The mix of personal research, an environmental engineering course and one particularly persuasive episode of Cosmos made him see the necessity of sustainable design. With construction being one of the biggest emitters of carbon, and the estimated potential 200 million people being displaced by the end of the 21st century because of climate change, there is a glaring need for the development of new sustainable technologies and material.

ModulusTech tackles two birds with one stone as population growth and carbon emission are on a dangerous rise. They stand by the firm belief that the integration of sustainable solutions with renewable energy is our only hope for saving the environment and ourselves.

The startup is currently working on improving their designs and testing new materials. You can learn more about the startup on their website, or follow their progress on facebook and twitter.